Beam Layout Welding Jobs

The application of beam layout welding and H-beams is very different. However, it's not restricted to what it can be used for. These are just a few factors that can help you tell if an H beam is an I beam.

This platform has rail guards for safety and stairs to make it easy to access. The platform is designed to store flux and wire. This allows for easy access for the operator to load flux and reels, as well as change drums and reels. You can increase the productivity, speed, and ability of your Beam Layout Welding operation by adding auxiliary equipment, such as PHI's Flange Turning Device and Beam Turning Device.

The flux recovery system allows you to recover and dispense welding flux. Seam Welder Hydraulic Power Units (also known as Electric Controls) drive the conveyors at entry and exit.

The application of beam layout welding and H-beams is very different. However, it's not restricted to what it can be used for. These are just a few factors that can help you tell if an H beam is an I beam.

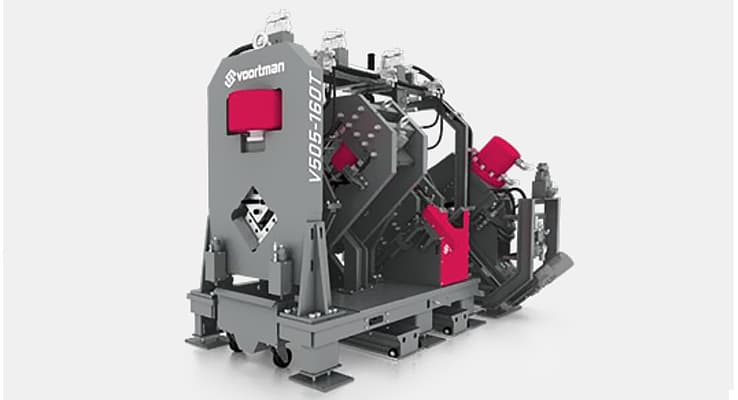

Beam Layout Welding consists of a trolley, a vertical column, an upper platform, tool carrier mechanism, seam tracking device and wire feeding device. Wire reel supporter, flux recovery, electrical control system, and SAW weld power.

The Conveyor System allows continuous beam production by connecting the Beam Layout Weldings, Tacking Fixture, and Automatic Welder. The Conveyors can be found at the entrance and exit to Seam Welder's Tacking Fitture, Automatic Welder, or Seam Welder. They are hydraulically controlled. The control stations at each station determine the direction, speed, and movement of adjacent conveyors.

The web, which is the center or height at the beam, usually determines the beam's strength. H beams are more strong because they are thicker. But, I beams have a better and more resistant flange than H beams.

Gulf States Saw & Machine Company�s Service Department is what keeps the company together. There is no other department like it in the south. The service department is currently composed of close to 30 people, with 24 Field Service Engineers strategically placed throughout Capital's 12-state regions. To help you expedite any service requests, we offer an online Service Request form. We have multiple staff members who answer customer calls. These are just a few of the reasons why Capital's quality team is regarded as the best in the industry and they strive for excellence in service delivery.

A welded beam consists of three individual sections of steel – a web, a top flange and a bottom flange. These segments are merged together with deep fillet welds to create an incredibly robust building material.